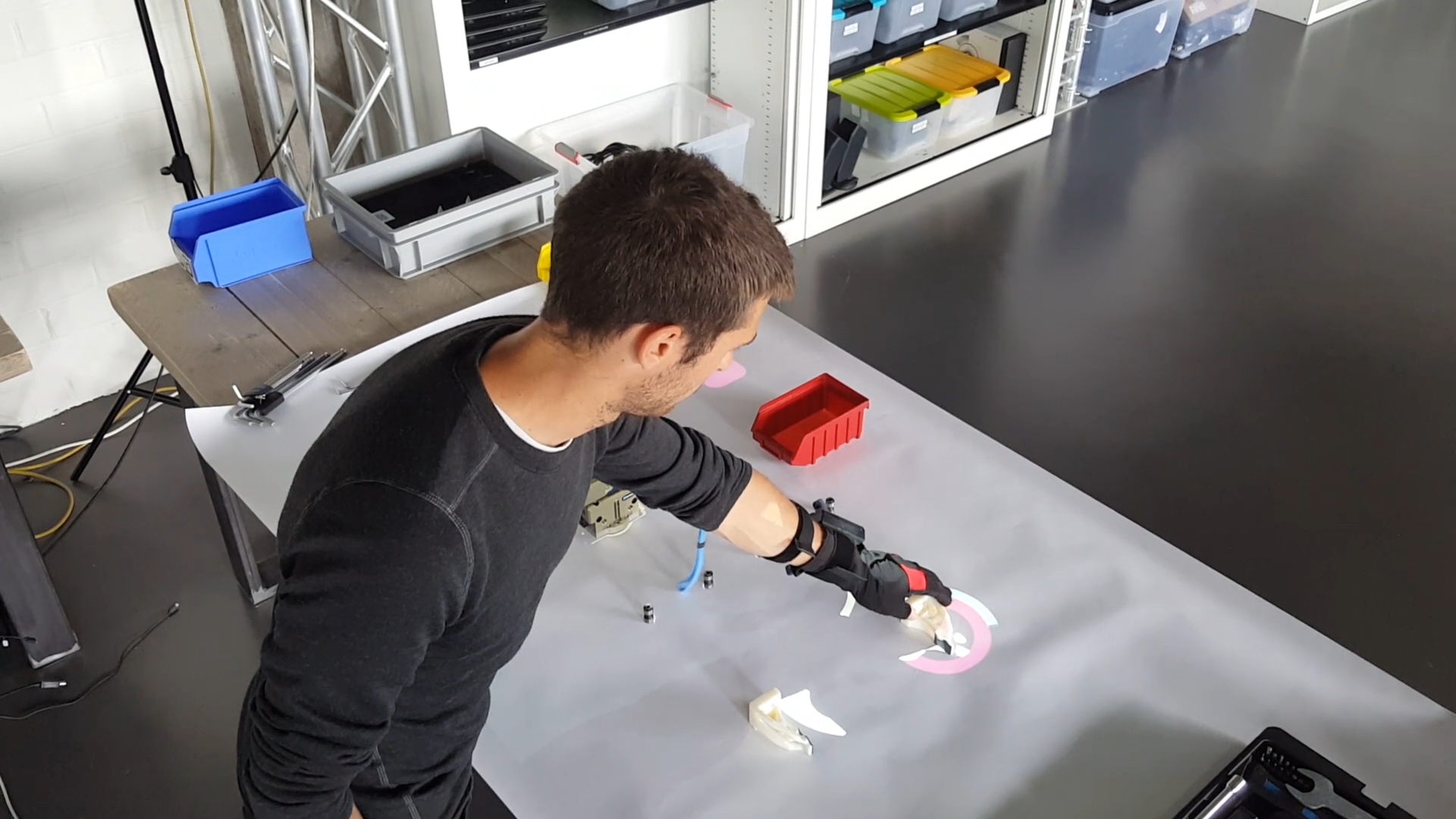

With this “Sector Innovating Virtual & Augmented Reality” project, partners and external organizations are guided in defining this added value in their current workflow. The project consists of two parts: a first part aimed at developing concrete proofs of concept where VR and AR technology is applied within the industrial sector and a second part aimed at a broader knowledge transfer for partners from other sectors.